Panels

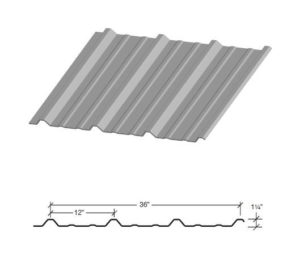

PBR (roof and walls)

The PBR panel is commonly used for a wide variety of architectural, agricultural, commercial, and industrial applications. PBR is a structural panel and an exposed fastener panel that can be used for both roof and wall applications. The minimum roof slope for PBR is 1/2:12.

Features and benefits:

- UL 790, Class A for external fire and roof assembly for UL 263 for internal fire.

Product Specifications:

Applications: Roof and wall

Coverage Widths: 36″

Rib Spacing: 12″ on center

Rib Height: 1 1/4″

Minimum Slope: 1/2:12

Panel Attachment: Exposed Fastening System

Gauges: 26 (standard); 29,24 (optional)

Finishes: Smooth

Coatings: Galvalume, Titan 200, Titan 300

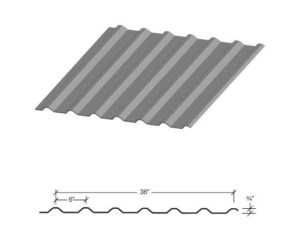

R Panel (roof and walls)

The R panel is an exposed fastener system that can be used for both roof and wall applications. The R panel can be installed directly over the purlins or joists. R panels are recommended for 1:12 or greater roof slopes.

Features and benefits:

- Numerous UL 580 ratings are available, as well as UL 790, Class A for external fire and roof assembly for UL 263 for internal fire and the UL 2218 Class 4 impact rating.

- R panels carry Florida approval

Product Specifications:

Applications: Roof and wall

Coverage Widths: 32″ wall, 29.33″ roof

Rib Spacing: 6″ on center

Rib Height: 3/4″

Minimum Slope: Minimum 1:12

Panel Attachment: Exposed Fastening System

Gauges: 26 (standard); 29,24 (optional)

Finishes: Smooth

Coatings: Galvalume, Titan 200, Titan 300

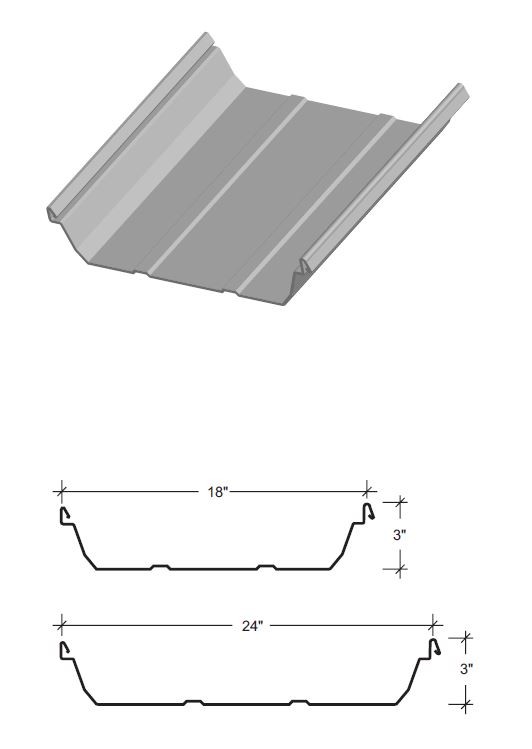

Standing Seam Roof

The Ultra-Dek® roof panel is a snap-together, trapezoidal leg standing seam roof system. Ultra-Dek® panels are available in 12-inch,

18-inch and 24-inch widths. Ultra-Dek® requires a minimum slope of 1⁄4:12 and is ideal for industrial, commercial and architectural

applications. Ultra-Dek® can be erected on various types of construction.

Features and benefits:

- Begins and ends in the high, reducing the risk of leakage at the rake

that can occur when finishing in the low. - Low and high clips are available to allow for various thicknesses

of insulation to be installed between the panels and purlins. - Numerous UL 580 Construction rating are available, as well as UL 790,

Class A for external fire, numerous roof assemblies for UL 263 for

internal fire and the UL 2218 Class 4 impact rating. - Ultra-Dek® carries Florida approval rating.

Product Specifications:

Applications: Roof

Coverage Widths: 18″, 24″

Minimum Slope: 1/4:12

Panel Attachment: Concealed Fastening System; Low, High, Fix and Sliding

Gauges: 24 (standard); 26 (optional)

Finishes: Smooth

Coatings: Galvalume, Titan 200, Titan 300

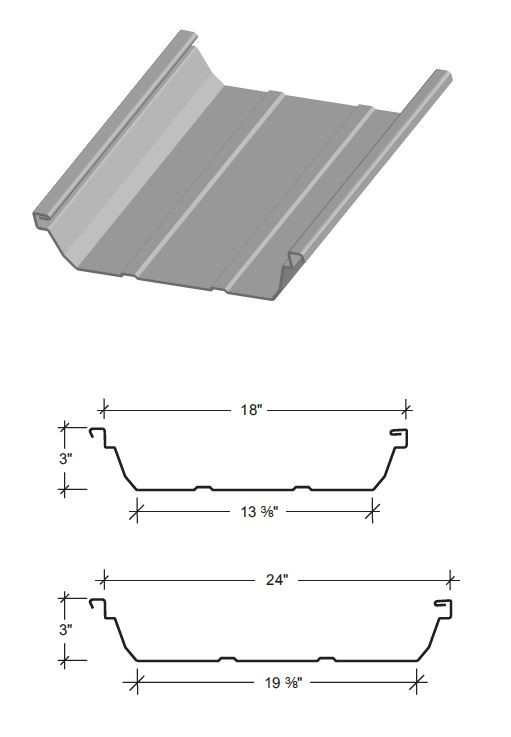

Standing Seam Roof

The Double-Lok® roof panel is a mechanically field-seamed, trapezoidal leg standing seam roof system. Double-Lok® panels are

available in 18-inch and 24-inch widths. Double-Lok® requires a minimum slope of 1 ⁄4:12. Double-Lok® panels are ideal for industrial,

commercial and architectural applications.

Features and benefits:

- Designed to cope with the forces of expansion and contraction. This is

accomplished by allowing the panels to freely move up and down the

roof slope. - 2″ and 4″ sliding clips are available in high and low versions, which

allow thermal movement on a wide variety of building widths. - Numerous UL 580 Construction rating are available, as well as UL 790,

Class A for external fire, numerous roof assemblies for UL 263 for

internal fire and the UL 2218 Class 4 impact rating. - Double-Lok® carries FM, Florida approval and Dade County ratings.

Product Specifications:

Applications: Roof and wall

Coverage Widths: 18″ and 24″

Minimum Slope: 1/4:12

Panel Attachment: Concealed Fastening System; Low, High, and 2″ Stand Off Sliding Clips

Gauges: 24

Finishes: Smooth

Coatings: Galvalume, Titan 200, Titan 300

Building Framing

Building Components

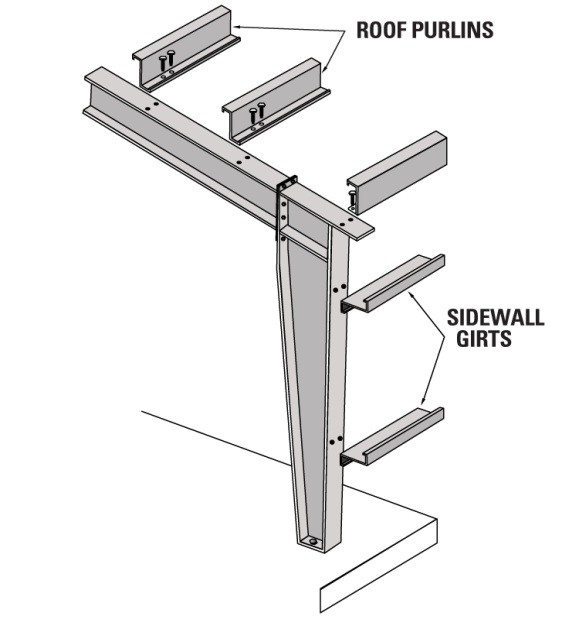

Z Purlin

A Z purlin is a horizontal structural member which supports roof covering and is in the shape of a Zee.

Feature:

- EZ purlin 1/2″ variance in flange width & 50 degree angled stiffener lip

- Nominal purlin spacing of 5′

- 50+ combinations of size, gauge, spacing and lap length

- Pre-painted, factory baked red oxide finish with optional galvanized finish

- Purlin clips welded to frame

- Tabbed sag angles are used with standing seam systems

- Easy purlin identification (triangle)

- Members of LGSI

- With a wider width and higher gauge zee-purlin, we can go to longer bays up to 40′

Z Girt

A Z girt is a horizontal structural member which supports vertical loads. Used to support and attach wall covering.

Feature:

- Girt clips welded to frame

- Flush girts with girt face in the same plane as column face

- Combinations of size, gauge and spacing

- Standard girt spacing, first girt at 7′-3 3/4″ and maximum of 6″ there after. Other spacing available for design

- Pre-painted, factory baked red oxide finish also available galvanized

- Bypass girts

- Low girt option available on request at 3′ 6″

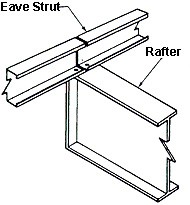

Eave Struts

An eave strut is a structural member located at the eave of a building which supports roof and wall paneling.

Feature:

- Heavy design, larger section which allows for straighter and stronger walls and eaves.

- Custom fab for each roof slope which provides greater support for roof panel at eave

- One piece construction will minimize field labor

- Can be extended lengths for endwall canopies which will allow for flexible design

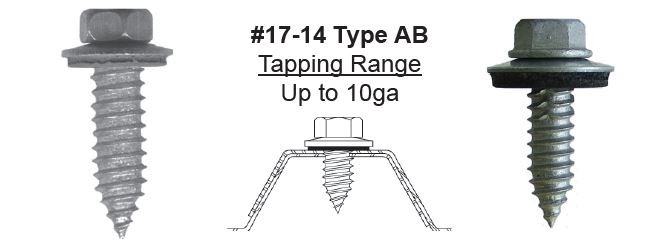

Fasteners

We offer zinc fasteners and carbon steel shafts as well as stainless steel hardware for our steel building kits. Both are long life fasteners.

Feature:

- Manufactured with a VRT technology with 3-1/2 times more back-out resistance than standard thread

- Taping range of up to 10 gauge

- Tri-Seal long life coating which prevents against rust

- Lifetime warranty

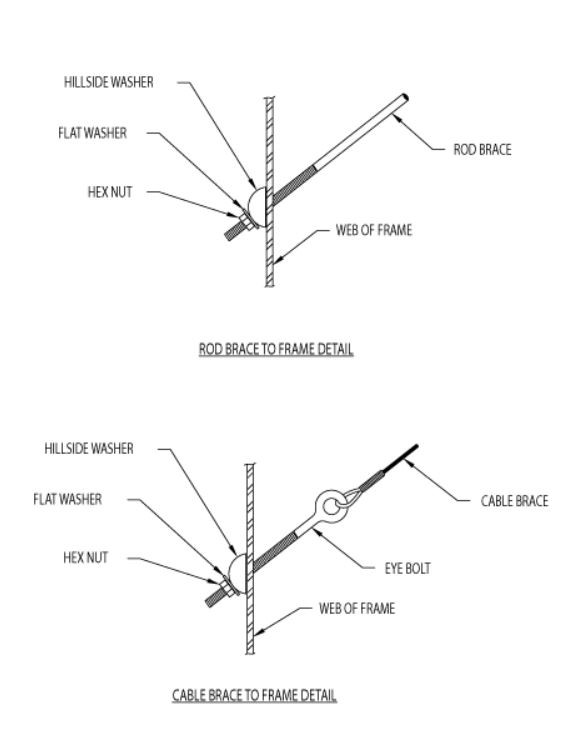

Bracing

Solid Steel Rod Bracing

Solid steel X bracing is a tension only bracing system. It may be located in the roof and walls of a building between frame members, transferring longitudinal forces to the foundation. It is the preferred bracing system for buildings being insulated or having interior wall coverage as they do not need to be maintained or tightened.

Cable Bracing

Cable bracing is a tension only X-bracing system. It transfers longitudinal loads to the foundation in smaller lower height buildings. It does have limitations due to capacity constraints for buildings with mezzanines, cranes or in high seismic areas.